Tel:+86-18221764758

Tel:+86-18119627750

Service and Complaints Hotline:+86-0551-6237 9896

Address:No.1 Yanglin Road, Baiyan Science and Technology Park, High tech Zone, Hefei City, Anhui Province

Service time:9:00-18:00

E-mail: dx@shinhoo.com

We look forward to your letter!

Products

Products center

CMB, CMB(L) particle resistant and dry grinding resistant fluoroplastic magnetic pump

CMB/CMB(L) series fluoroplastic magnetic pumps use ANSYSICEM CFD, CFX finite element analysis and fluid visualization simulation technology to design high-performance hydraulic models. The pump body, impeller, impeller and isolation sleeve are designed with solid particle blocking ring structure to reduce particle wear: the support shaft adopts a fixed shaft wide fulcrum non-cantilever support structure, which eliminates the trouble of shaft breakage of the shaft drive rotor and has better stability: reinforced sleeve made of non-metallic materials, the damage caused by magnetic eddy current heating is completely eliminated, and the operation reliability is improved: PLUS SSiC composite ceramic manufacturing sliding bearing components not only resist the wear of solid particles, but also can withstand the empty operation for 30min under the evacuated state. CMB(L) is designed with a long suspension body structure with bearings, which can prevent the high temperature of the medium under high temperature conditions from affecting the operation of the motor.

Category:

Keywords: aquaculture environmental protection sewage

- Description

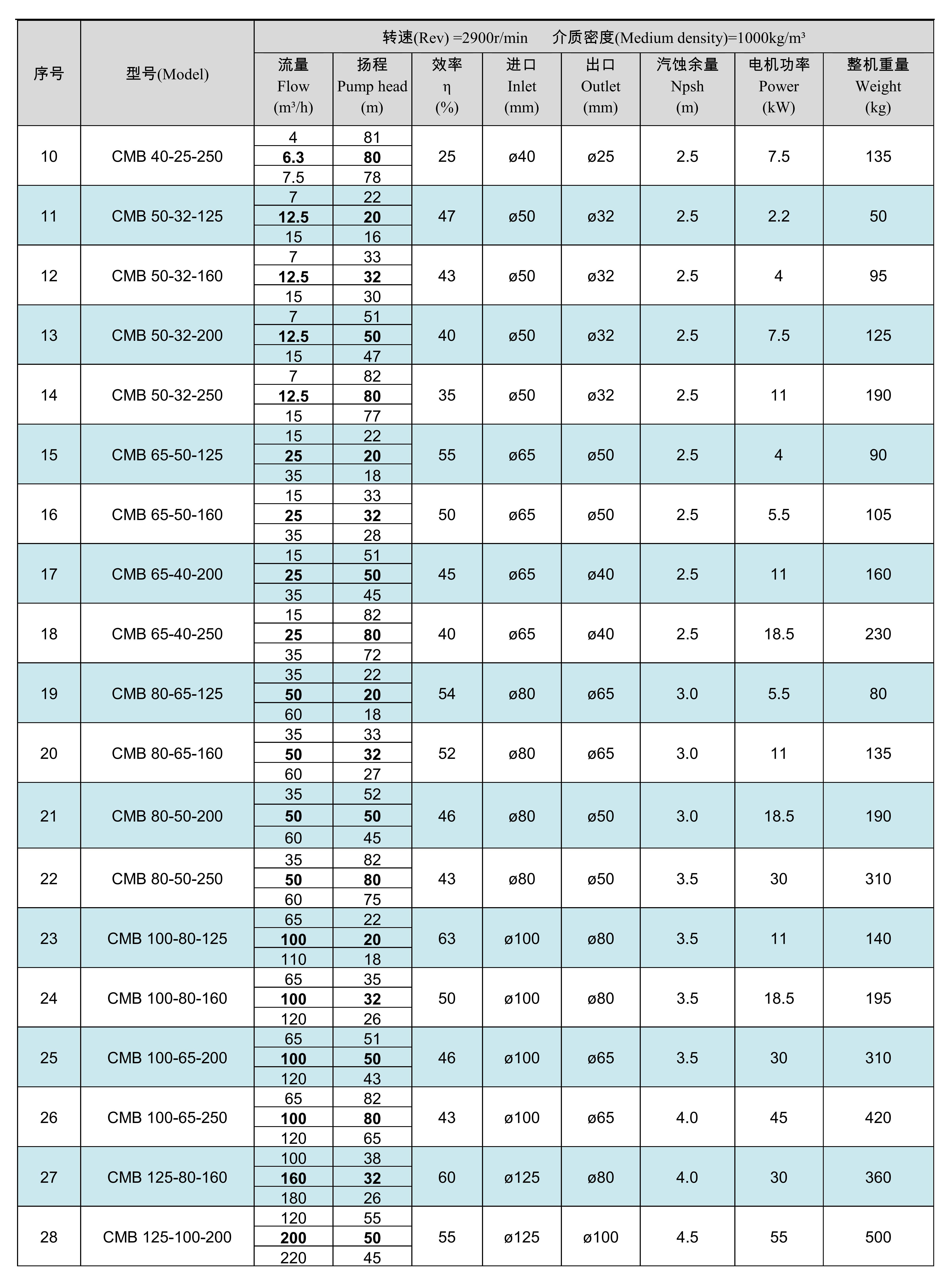

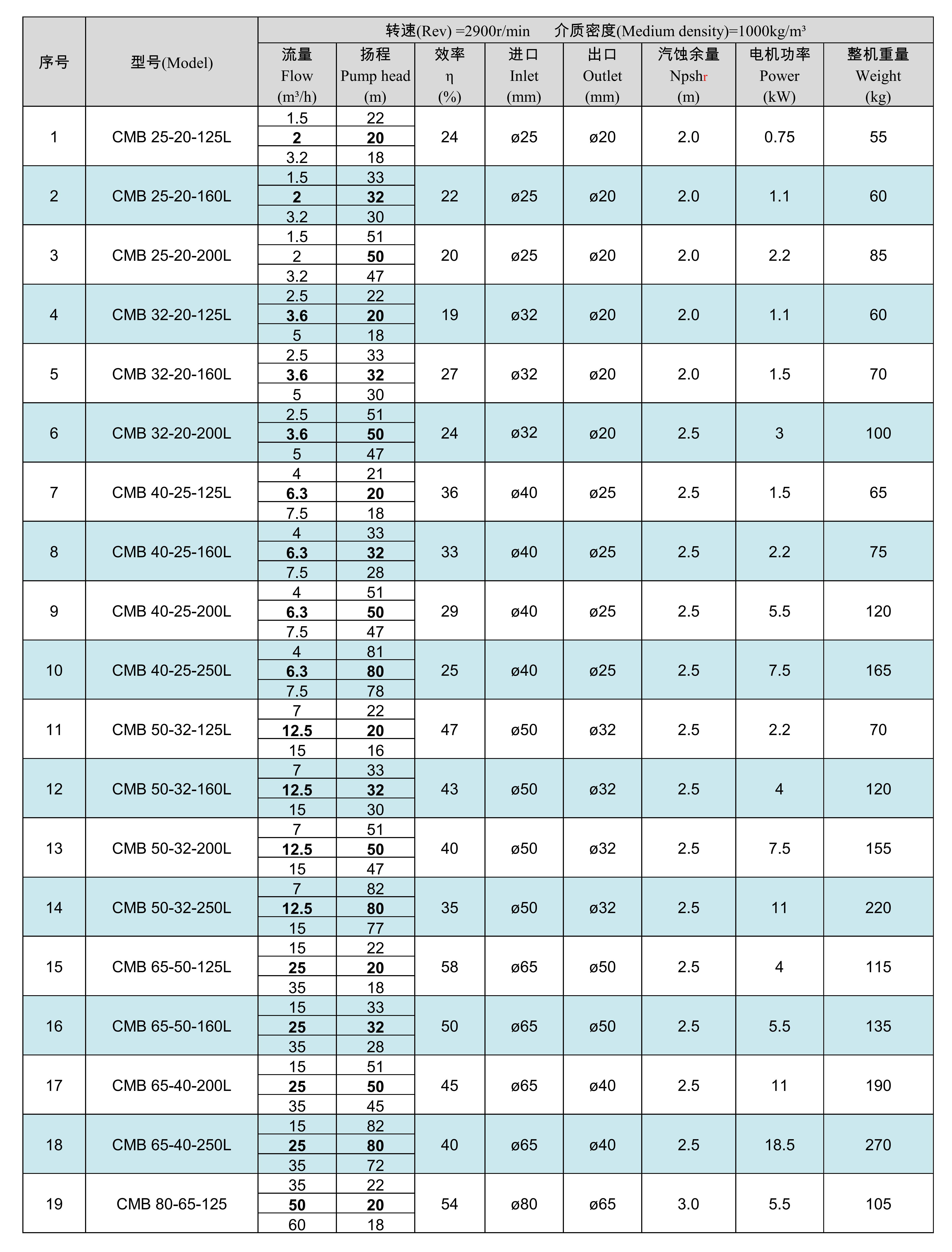

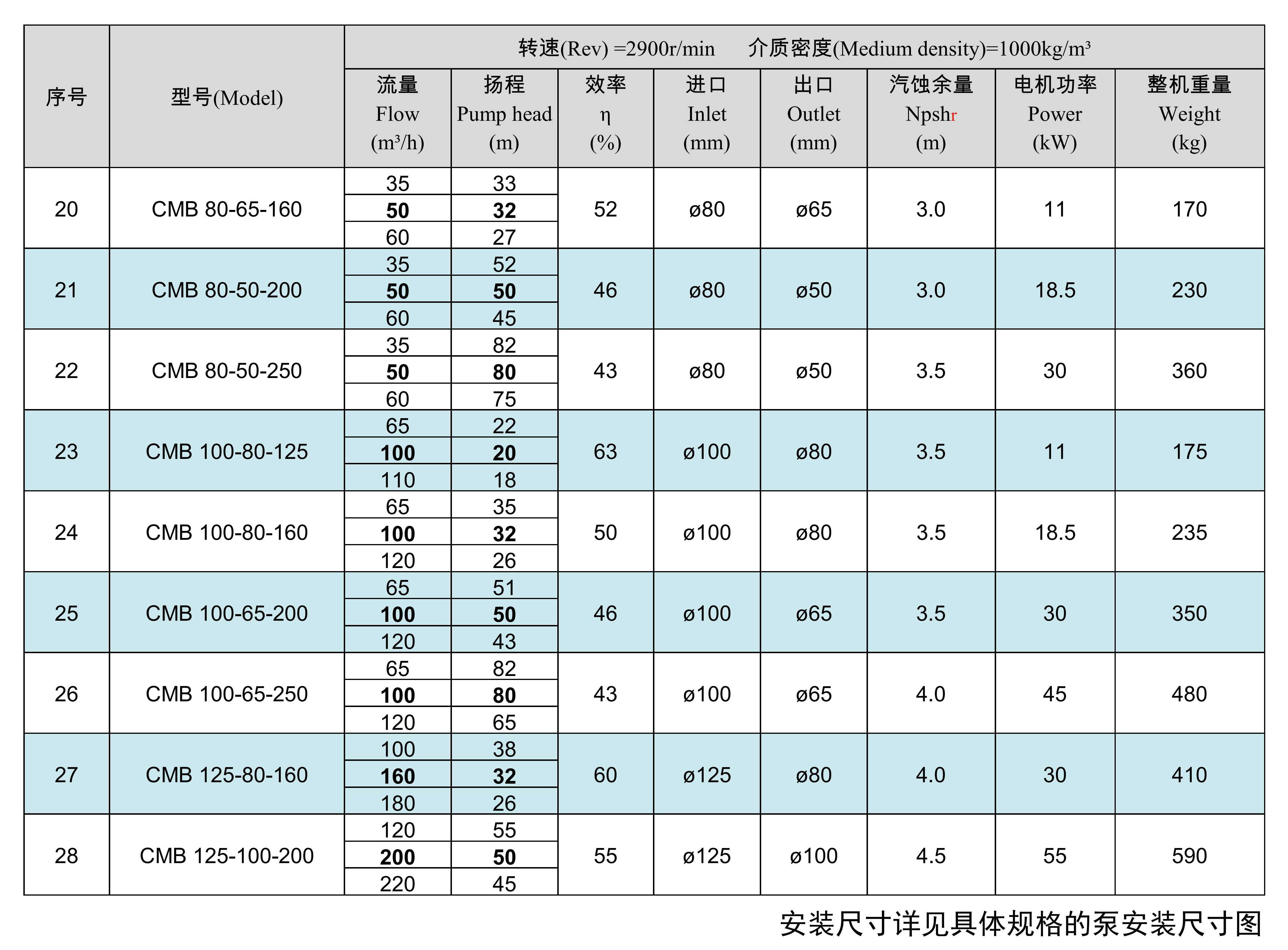

- Technical Parameter

- Application Area

-

- Commodity name: CMB, CMB(L) particle resistant and dry grinding resistant fluoroplastic magnetic pump

CMB/CMB(L) series fluoroplastic magnetic pumps use ANSYSICEM CFD, CFX finite element analysis and fluid visualization simulation technology to design high-performance hydraulic models. The pump body, impeller, impeller and isolation sleeve are designed with solid particle blocking ring structure to reduce particle wear: the support shaft adopts a fixed shaft wide fulcrum non-cantilever support structure, which eliminates the trouble of shaft breakage of the shaft drive rotor and has better stability: reinforced sleeve made of non-metallic materials, the damage caused by magnetic eddy current heating is completely eliminated, and the operation reliability is improved: PLUS SSiC composite ceramic manufacturing sliding bearing components not only resist the wear of solid particles, but also can withstand the empty operation for 30min under the evacuated state. CMB(L) is designed with a long suspension body structure with bearings, which can prevent the high temperature of the medium under high temperature conditions from affecting the operation of the motor.

CMB/CMB(L) series fluoroplastic magnetic pumps use ANSYSICEM CFD, CFX finite element analysis and fluid visualization simulation technology to design high-performance hydraulic models. The pump body, impeller, impeller and isolation sleeve are designed with solid particle blocking ring structure to reduce particle wear: the support shaft adopts a fixed shaft wide fulcrum non-cantilever support structure, which eliminates the trouble of shaft breakage of the shaft drive rotor and has better stability: reinforced sleeve made of non-metallic materials, the damage caused by magnetic eddy current heating is completely eliminated, and the operation reliability is improved: PLUS SSiC composite ceramic manufacturing sliding bearing components not only resist the wear of solid particles, but also can withstand the empty operation for 30min under the evacuated state. CMB(L) is designed with a long suspension body structure with bearings, which can prevent the high temperature of the medium under high temperature conditions from affecting the operation of the motor.

The pump has the incomparable advantages of similar fluorine plastic magnetic pump, such as particle resistance, dry grinding resistance, high efficiency and energy saving, stable operation, quiet low vibration, high reliability, long life, etc., breaking through the traditional fluorine plastic magnetic pump use restrictions, is a strong corrosion, toxic, volatile, flammable and explosive, organic solvents and valuable liquid ideal environmental transport equipment. Use temperature range:-20C ~ 150C

magnetic pump

It is a static seal pump, which is composed of impeller, inner magnetic rotor, outer magnetic, motor, etc. The motor drives the outer magnetic rotation, and the magnetic force passes through the isolation sleeve and acts on the inner magnetic rotor to make it rotate. The inner magnetic steel and the impeller are integrated without shaft seal, and the liquid medium is sealed by the isolation sleeve to realize no leakage of the conveying liquid. -

-

Suitable for conveying strong corrosive clear liquid. For example: hydrochloric acid, nitric acid, organic solvents.

Related Products

Double suction open centrifugal pump

OTS type double-suction open centrifugal pump series Our company has developed and innovated a new generation of series products on the basis of traditional products S, SH and SA series, with a wide range of performance and the ability to use multiple purposes.

1, high efficiency, energy saving: the operating efficiency is 3-10 percentage points higher than the average pulp pump, energy saving, consumption reduction of 15-30%; 2, good cavitation performance, long life: the actual service life than ordinary pulp pump can be increased by 2-3 times; 3, high concentration, no clogging: conveying pulp concentration of up to 6%;

Intelligent constant pressure water supply equipment

Frequency conversion constant pressure water supply control cabinet (hereinafter referred to as the control cabinet) is my company on the basis of the original fourth generation control cabinet, in accordance with the requirements of the ISO9000 quality system research and development of new control cabinet, we integrated the needs of the majority of users for ten years, with reference to the latest standards, using the latest microcontroller technology, combined with high reliability design, developed control cabinet has higher reliability and stability.

SP stainless steel deep well submersible pump

The hydraulic parts of the pump body adopt sand-resistant structure design, and the number of stages is small, so the sand-passing capacity and service life are improved; Using permanent magnet synchronous motor starting torque, low voltage can be easily started; The whole machine is equipped with a new type of frequency conversion controller, which has high control accuracy and little damage to the motor.

Message